If you are reading this, there' a good chance you already work at an asset-intensive organization.

No matter what your role may be. Engineer. Planner. Production Supervisor. Senior Manager. You'll almost certainly have some part to play in managing assets that create value for your business.

Asset Management is everyone's business. And so, it follows that everyone will have a stake in your Enterprise Asset Management (EAM) system.

Or, at least, they will when you decide which one to get.

What are the EAM Requirements for Delivering Value?

Look out across your factory, your facility, your plant.

Among the sea of pipework, cabling and steel vessels, you'll see your portfolio of physical assets delivering saleable output. Assets delivering the right product, at the right cost and at the right time.

That is to say, real value.

Enterprise Asset Management, simply put, is to manage the activities within the lifecycle of assets, both their physical movement and condition and their associated financial information, to ensure that the organization’s objectives with these assets are achieved.

E-ISG Asset Intelligence, LLC.

People, processes, technology, data, assets and software intertwine endlessly to 'hit the numbers' and keep the customers coming back for more.

But if you've been in the game long enough, you'll know that you need an asset information system on a reliable software platform to bind it all together.

To give it coherence and control.

EAM systems are a key feature for delivering that long term value for asset-intensive organizations over the whole asset life cycle.

If you are looking for a new EAM or you're just a curious observer, then read on…

14 EAM Features That Should be on Your Checklist

1. Asset Hierarchy

This is where it all starts.

Your asset hierarchy or directory will give your organization a solid foundation for asset criticality, life data, asset categories, condition, and locations. By having your physical assets in a tree hierarchy, you can account for costs at all levels and attain business insights on cost, performance and risk for assets, lines, areas and plants. You can focus your maintenance plans on different levels.

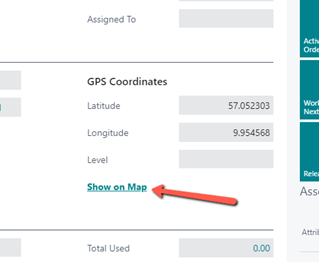

The best EAMs allow you to import an existing hierarchy and key asset information via a spreadsheet. You can upload photos and documents and even assign GPS co-ordinates for maintenance technicians to quickly locate assets out on the plant.

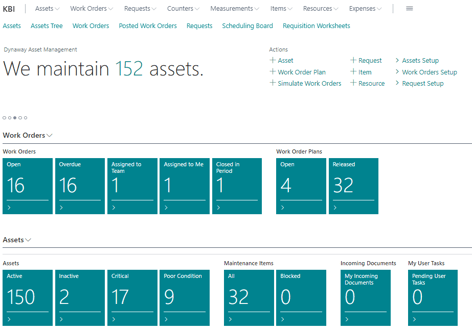

2. Work Order Management

Do it the right way and your organization will reap the benefits: a transformation in productivity, maintenance effectiveness and

decision-making. Your EAM system must be able to handle this. It's non-negotiable.

A good work management module will allow maintenance engineers to report work order status and progress in real-time, consume spare parts, and quickly and efficiently complete work orders on a mobile device or back at the office.

3. Document & Information Storage

It goes without saying that the era of paper is gradually coming to an end. Piles of paper in old filing cabinets is positively ancient these days. Modern EAMs will have a document and asset information storage function. Keep your PDFs, photos, manuals, reports, spreadsheets, and notes all in one place and one software repository.

|

Organisations should establish and maintain systems that manage asset information. The systems should be designed to provide sufficient support and information to meet the organisation’s asset management decision making objectives. The Institute of Asset Management: Asset Information, Strategy, Standards, and Data Management |

4. Cost Tracking and Control

A good EAM will make it easy and agile.

You can understand costs from a whole plant level down to asset component level (e.g. a bearing on a conveyor) or the combined cost of an asset and all its sub-assets (a production robot and all its servo drives).

With this cost data in your hands, you will get valuable business insights. For example, 'repair or replace' decisions will be much easier. You'll have a greater understanding of life cycle costs (total cost of ownership) and be much more confident when making those difficult asset replacement decisions in the boardroom.

Arm yourself with data, not gut feeling.

5. Time-based Maintenance

This comes nicely back to the work management piece of the jigsaw. Any EAM worth the investment will easily handle time-based maintenance. These are sometimes known as PPMs or Planned Preventive Maintenance. They can be maintenance tasks triggered by mileage, run hours, or widgets made. The EAM system will emit work orders when trigger points are reached.

6. Condition-based Maintenance

CBM is performed when condition monitoring indicators show that an asset is going to fail or that critical performance is deteriorating. In the best-in-class EAMs you can specify condition assessments and trigger maintenance work orders based on these assessments.

Condition Monitoring is a crucial piece of modern maintenance management and asset strategy.

Get on board, don't get left behind.

7. Failure Reporting

You and your organization need this functionality.

It's as simple as filling out a completed work order after a job or using failure, repair, and action codes in the EAM.

Failure data and information is like fuel for reliability engineers. It's what gets them out of bed in the morning. Without it, they are a pale shadow of themselves and will be lost to the world.

Failure data is precious. Inputted consistently, simple words can lead to great insights and analytics. It'll help your reliability engineer improve availability and feel like a human again. So, why not make it easier for them?

8. Downtime

The best EAMs allow you to track downtime. From this simple piece of data and a few others, you can be informed on availability, maintainability, and reliability. Yes, that's a lot of abilities. But if you measure these, you are at least somewhere on the road to high performance, low costs, and low risks—those central ideas of good asset management.

9. Planning

You should be able to plan work orders automatically and manually. Modern EAMs optimize the work order plan based on different parameters such as engineer capabilities or skills, availability, tools, resources, trade type, expected start date, and task priority or criticality.

10. Resource Planning & Allocation

When you think about it, how can you plan a task and carry it out effectively if you don't have the right resources to do so? Technicians and engineers' times have to be planned out and used effectively and efficiently to achieve asset management goals.

The best EAMs facilitate this for you.

11. Spare Part Planning and Management

Professional spare parts and inventory management are a key feature of world-class maintenance organizations. And a vital feature of the best EAMs. If you get your spares philosophy wrong, it can dramatically impact mean time to repair (MTTR) and availability, increase operating costs and tie up cash on shelves that could be put to better use elsewhere in the business.

Get yourself an EAM that can handle this.

12. Maintenance KPI's

Your organization's levels require access to dynamic maintenance and operational information as a driver for performance improvement. If you work towards OEE targets, then you'll know what we are talking about.

Your EAM system must have the capability for maintenance performance to be digitally analyzed through key performance indicators (KPI). They give you an immediate sense of direction, performance, and perspective.

13. Reports

Who doesn't want or need reports?

All that asset data, failure history, spares costs, and labor utilization information that resides in the EAM needs to come out if you want to make improvements and make the best business decisions.

A good EAM will offer you a range of management reports on all sorts of data in the form of spreadsheets, CSV files, and PDFs, among others.

14. Flexible deployment and integration

We find ourselves cruising into this new age of IIoT and digitalization on an industrial scale. Change is all around us. This means savvy customers now want the flexibility of deployment. They want scalable and mobile solutions. This means tablets, smartphones, PCs, laptops, and cloud-based software. And flexible pricing plans. Not everyone wants or needs a premium product.

The best, modern EAM solution providers will offer you all this as a matter of course.

On top of all these EAM checklist features that we've discussed, make sure that your EAM provider offers great vendor support and services. This means they are easily accessible when you need them, they listen to you, they explain things simply, and they train you if necessary.

-1.png?width=388&height=200&name=Webinar%20MS%20AM%20Mobility%20(2)-1.png)