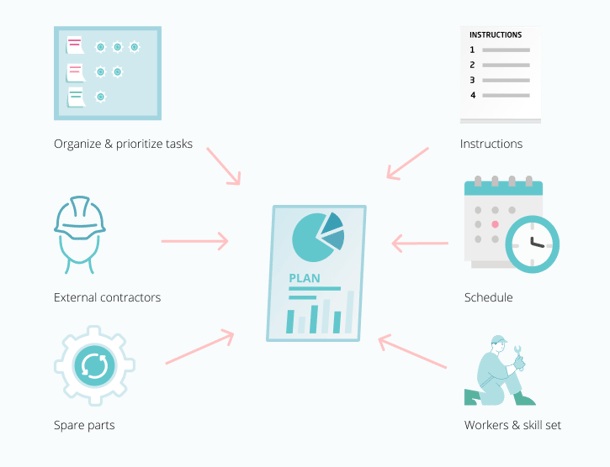

Effective maintenance planning is essential to the overall maintenance environment. The maintenance plan's contents, which include the actual work, instructions, schedule, workers, spare parts, and contractors, guide all the maintenance work activities. Read on to learn what you need to include in the plan and how to make it efficient.

KEY TAKEAWAYS

- Maintenance planning ensures sustaining the proper working condition of the equipment.

- Essential contents of any effective program are exhaustive inventory of assets, identification of the specific maintenance tasks, their alignment to specific assets, reasonable maintenance schedule, indication of the appropriate skill set for each maintenance task, prediction regarding spare parts consumption and specification of the work that contractors will do.

- Omitting any of above mentioned essential contents is likely to result in a weakened plan.

(Plant Engineering, 2020)

What is a maintenance plan?

A maintenance plan is a document that defines work done to maintain assets in a facility proactively. The contents of the document help you facilitate the continued use of an asset at optimum performance. Your facility can avoid significant breakdowns or unforeseen renewal if you stick to the guidelines provided here.

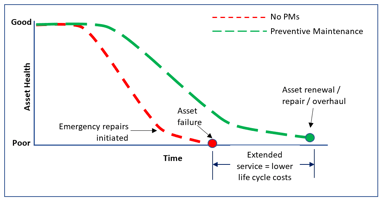

The idea behind maintenance planning is to ensure that you can sustain the proper working condition of your equipment. While an ordinary plan will get the job done, any facility requires an effective program to enjoy the full benefits of your maintenance policy.

What makes a maintenance plan effective?

An effective plan needs to cover all the features of your facility's maintenance policy. The program should contain an exhaustive inventory of assets that you need to maintain. The list which includes numerous items like boilers, pumps, and roofs, ensures that you don't leave out any vital asset.

You'll also need to identify the specific maintenance tasks you intend to perform. Where possible, align these tasks to individual assets. A reasonable maintenance schedule should also suffice in guiding the whole maintenance program.

For the efficient maintenance of your assets, you need to demonstrate the skills-set required for each maintenance task. You don't want to hire an inadequately skilled individual to handle the maintenance. The different levels of maintenance could help you as you prepare this section.

Exactly what do we need to plan?

The work itself

As you create your maintenance plan, you have to be clear on what exactly you need to do. Decide the priority areas as well as the sequence of activities once the maintenance work begins.

Instructions

Proper instructions limit the dependency on specific workers. The maintenance work also needs to meet particular quality standards. You'll only be able to achieve such standards if you include explicit instructions in the plan. While at it, consider including job observations that you can perform to guarantee the efficiency of the maintenance tasks.

Schedule

The purpose of the schedule is to do the work as often as needed – not over-maintaining by doing the work too often – not under-maintaining so that you experience downtime and breakdowns. While weekend maintenance hardly stands in the way of your operations, there is a chance that you may fail to find suppliers.

It is always wise to set aside the maintenance window when you begin your year. Ensure that production is well aware of this window. You'll need this team's utmost cooperation during this period. As the year wears on, make necessary changes to the plan to increase its efficiency.

Workers

The plan has to indicate the appropriate skill set for each maintenance task. This information will inform your choice of the best contractors for the work. Depending on your organizational arrangements, assign each member of the maintenance team to specific areas.

While at it, indicate the tasks that you will reserve for outside contractors. Ensure that the plan also limits access to areas that pose high risks to the facility's employees.

Spare parts

In this phase, you can predict your spare part consumption. Once you indicate the parts that you'll need, the worker knows exactly what to pick from the store – before he goes to do the actual maintenance work. With this section, the maintenance manager gets insight into parts used in the previous period as well as future part consumption. They'll have an easier time preparing a budget for the next twelve months.

Contractors

Some maintenance tasks may require outside contractors. They include external specialists who come on-site to do specialist work. Most of them bring special equipment like mobile cranes and metering equipment tools to service assets.

The effective maintenance plan specifies the work that you'll request contractors to do. With this section, you won't have to count on one specific contractor for all your maintenance tasks. You could use these specifications to request quotes and tenders from different contractors to do a particular type of work.

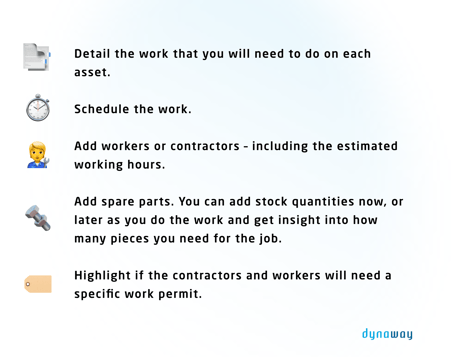

Steps to creating an effective maintenance plan

- Detail the work that you'll need to do on each asset. While at it, write a procedure that workers will understand.

- Schedule the work – Use a dating frequency, running hours, or measures that will provide insight into the condition of an asset. The schedule allows you to do predictive maintenance.

- Add workers or contractors – including the estimated working hours.

- Add spare parts. You can add stock quantities now, or later as you do the work and get insight into how many pieces you need for the job.

- Work permit: Highlight if the contractors and workers will need a specific work permit.

What happens if we remove one/many topics from the plan?

All the contents mentioned above join together to create an efficient maintenance plan. Any omission is likely to result in a weakened plan. If you leave out the work, there is a chance that you may do more than is necessary and spend unwarranted resources.

Once in a while, you may have to work with less-experienced personnel. Failing to include instructions in your plan will give them a hard time. Maintenance plans without a schedule often place facilities in 'firefighting' mode. You won't be in a position to maximize the performance of your assets throughout the year.

Without a section indicating the spare parts needed for maintenance tasks, you will have a hard time budgeting for your maintenance program. The absence of sections touching on workers and contractors from your plan predisposes your assets to shoddy maintenance.

Make the most of preventive maintenance

Any organization looking to maximize its returns on investment should have a maintenance plan. As you create one, ensure that you don't leave out any of the essential contents of an effective program – you run the risk of weakening the plan.

The idea of having a maintenance plan is to make the most of preventive maintenance while reducing downtime. You don't always have to be on firefighting mode.

-1.png?width=388&height=200&name=Webinar%20MS%20AM%20Mobility%20(2)-1.png)