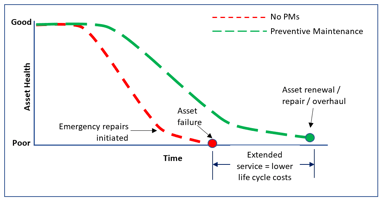

Preventive maintenance is a systematic maintenance strategy where work is carried out with the objective of increasing asset lifetime. This maintenance usually has repetitive work orders like cleaning, oil, repairs, and spare parts replacements.

Preventive Maintenance is all about avoiding the equipment failure rather than fixing what's already broken.

There are two main types of PM:

- Planned maintenance - regular proactive maintenance management based on sequences or supplier recommendations.

- Condition based maintenance - maintenance based on machine operator advice on measured values and performance indications like counter or time triggers.

What Does Preventive Maintenance Include?

Preventive maintenance involves regular inspection of equipment where potential problems are detected and corrected in order to prevent equipment failure before it happens.

In practice, a preventive maintenance schedule may include things such as cleaning, lubrication, oil changes, adjustments, repairs, inspecting and replacing parts, and partial or complete overhauls that are regularly scheduled.

One of the best practices for Preventive maintenance is to include Checklist for every piece of equipment.

Preventive maintenance includes much more than simply performing routine maintenance on equipment.

Next chapter: How to create Preventive Maintenance Plan?

Preventive Maintenance Software

For Preventive Maintenance it is not mandatory to have a CMMS or EAM solution, however, many organizations choose to implement one. EAM software will simplify a lot of work and processes when planning your maintenance.

First of all, preventive maintenance software backlogs all company's maintenance data which makes it easy to keep track for all regulations, compliances and inspections, repairs and replacements.

If you choose to have EAM that is integrates seamlessly into your ERP system, with the maintenance data stored in one place, preventive maintenance software makes it easy to manage work orders, purchase orders, inventory of spare parts and maintenance records.

This data can also help maintenance workers to allocate the appropriate working hours to change spare parts and diagnose problems when they occur on a piece of equipment. Most importantly, PM software helps not only to collect but also to organize maintenance data, so it is ready and available to maintenance workers whenever they need it.

Continue to read: All you need to know about Preventive Maintenance

-1.png?width=388&height=200&name=Webinar%20MS%20AM%20Mobility%20(2)-1.png)