Microsoft Asset Management is an advanced module for managing assets and maintenance jobs in Microsoft Dynamics® 365 for Finance Operations. Enterprise Asset Management integrates seamlessly with several modules in Microsoft Dynamics® 365 for Finance and Operations.

Microsoft Asset Management module helps you efficiently plan and execute tasks related to the maintenance and servicing your company’s assets. The set of features included within AM enables your machinery and equipment to work continuously without unnecessary interruptions or breakdowns.

Related Resources:

Webinar collection with Asset Management experts.

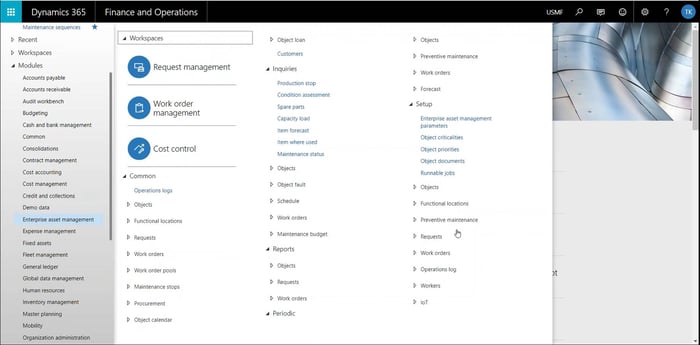

When you log in, you will be able to see a list of different workspaces.

On the left side menu, you can see the preview of the different modules available based on your predefined role on the ERP.

The Asset Management module is structured the same way as the other modules which exist on Microsoft Dynamics 365 Finance and Operations.

There are different maintenance processes which Microsoft Asset Management can facilitate:

Corrective maintenance is carried out after failure detection and is aimed at restoring an asset to a condition in which it can perform its intended function.

For condition based maintenance you can create maintenance plan based on counter values on an asset.

Preventive Maintenance / Predictive Maintenance

Preventive maintenance is proactive maintenance that is performed regularly at predetermined intervals in order to prevent asset failure.

With Microsoft Asset Management is possible to predict future maintenance tasks, based on data provided from the assets. Instead of doing preventive maintenance based on time, it can be predicted based on usage.

Based on asset properties and maintenance planning, work order can be created automatically or get an overview of larger period and plan before creating the work orders.

In Microsoft Asset Management an Asset is a machine or a piece of equipment that requires continuous maintenance and service. Assets can be created in a hierarchical structure. Maintenance jobs can be planned at all levels in the asset structure.

So that a work order to be created, there should be stated an asset which requires certain maintenance.

Useful Links: Spare Part Consumption

The work orders are staged-based processes which can be adjusted based on company’s operations.

How can work order be created?

Based on the type of maintenance, there are different way to create a work order:

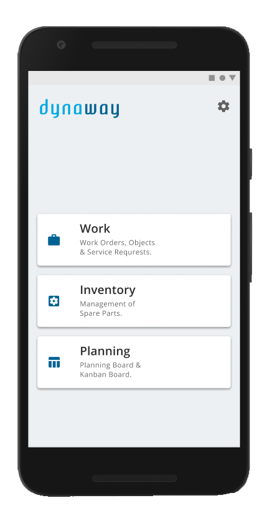

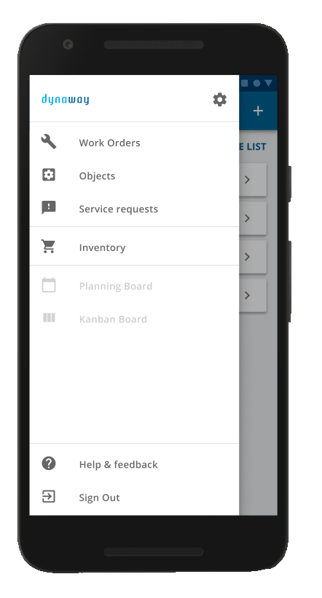

Dynaway Mobile EAM is a comprehensive offline capable client that supports a very wide variety of processes related to work order execution.The Mobile Client is a webapp. The Mobile Client can be accessed via any browser, which gives you flexibility with the devices you would want to use the Mobile Client on.

The Mobile Client has the following functionalities and information available:

Connected to Objects

Connected to Work Orders

Related Articles:

On the Mobile Client, a worker can see which tasks have been scheduled for the day or check the task overview for the week or the month.

By clicking on the work order, the worker can see the description of the task which can be added manually or a checklist attached to the task which needs to be executed.

The worker can get a full overview about the object maintenance history before executing a task and check requests, created for this object, which the worker can resolve.

Attachments can be added by the worker for documenting a work. For example, a picture can be added to show the result or the progress of a task. Guidelines can also be added to a task, if needed.

After the execution the worker can register the hours spent on the task and the used spare part consumption.

WATCH WEBINAR: Difference Between Asset Management Mobile Workspace and Dynaway Mobile Client

Download Inventory for Offline Use

When the Mobile Client is online, you can request item information, allowing you to see inventory status and create item registrations when the Mobile Client is offline. You can use offline item information to create item forecasts and item registrations. This is useful if you work on maintenance jobs in remote areas with limited or no internet coverage. The offline inventory can be used in a remote warehouse or as a stock list in your service van.

Read more about Offline Inventory

In the mobile solution for Dynaway Enterprise Asset Management, the Planning board module is used for planning unscheduled work order lines on individual workers.

Planners, supervisors, and managers can schedule and reschedule work order lines on the Mobile Client. Scheduling is updated in real time. You drag-and-drop a work order line from the unscheduled area to the calendar area to schedule it.

With the Planning Board you can:

With Advanced Asset Management Module you can: