The Dynaway Enterprise Asset Management system allows users to track spare parts on objects and object BOMs, which means you can follow item consumption on an object during the entire lifetime of the object. By this, you can reduce costs by optimizing spare parts handling.

Spare parts are managed in the Product information management module in Dynamics 365 for Finance and Operations. Spare parts consumption is registered on work orders in the Dynaway EAM solution. Replenishment of stock, including the spare parts ordering process, is done using standard Dynamics 365 for Finance and Operations functionality. Spare parts are set up on object types, which are related to objects. A spare parts list can contain a list of approved spare parts as well as spare part alternatives to be used in case approved spare parts are not available.

When you have created a work order, it is possible to add approved spare parts to the work order, if required. After you have completed a maintenance or service job, and item consumption has been registered on a work order, you are able to track consumption of spare parts and other items used on the object.

This functionality allows you to keep a complete item consumption record on all your objects. For example, you can use the record to monitor if a specific spare part is often replaced, or keep track of which spare parts or other items are currently used on an object.

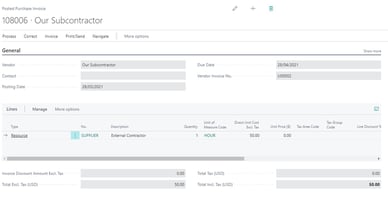

On the work order details screen Consume tab, you see a list of forecasts and actual registrations on the work order line. When you have completed the job, you can make registrations on:

- Hours

- Items

- Expenses

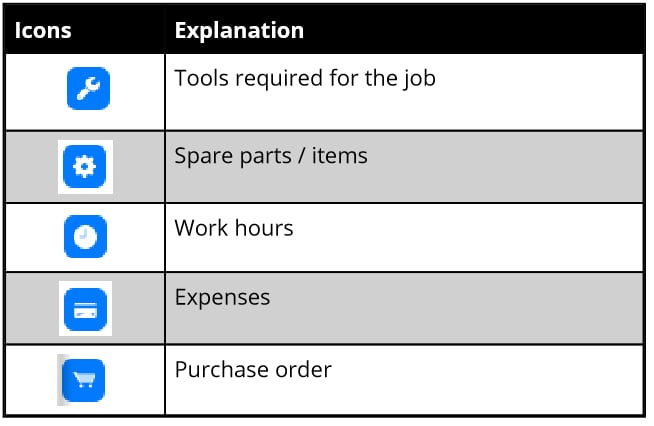

You can make registrations on a work order line several times, as long as the work order stage, which is selected on the work order, allows it. The table below shows the icons you may see on forecast lines and registration lines.

Researching on Mobile EAM functionality? You can find more information about Maintenance Planning, Work Order management and more features here.

.png?width=388&height=200&name=Copy%20of%20Blog%20Feature%20Image%20(6).png)

.jpg?width=388&height=200&name=Digital%20transformation%20(4).jpg)