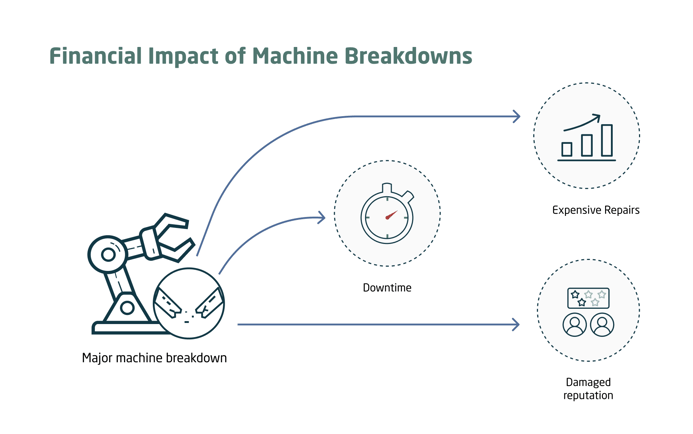

Imagine the financial impact of a major machine breakdown on your company's bottom line and reputation. It could cause significant downtime, expensive repairs or replacement, and potential damage to your reputation in the industry. Ultimately, the financial consequences could be disastrous for any asset-intensive company.

KEY TAKEAWAYS

- Accurate asset tracking reduces costs and improves utilization.

- Preventive maintenance extends asset lifespan and reduces downtime.

- Asset performance management software provides valuable insights.

- A comprehensive asset lifecycle approach improves financial outcomes.

Not using your Microsoft Asset Management software to its full potential? Find out how to get the most out of your Microsoft asset management here.

But don't panic just yet. There is a solution that can help you avoid these potential pitfalls. Enterprise Asset Management (EAM) software is a powerful tool that can streamline asset management processes and optimize financial performance.

Increase Operational Efficiency

However, it's not enough to only adopt an EAM software solution. To fully leverage its potential, it's crucial to integrate it with your Enterprise Resource Planning (ERP) platform. By doing so, you'll achieve faster and more accurate distribution of information, leading to better decision-making, and ultimately, financial success.

Let's explore the importance of EAM software from a financial perspective and highlight four ways to maximize financial performance by integrating an EAM with an ERP system.

1. Improved Asset Management

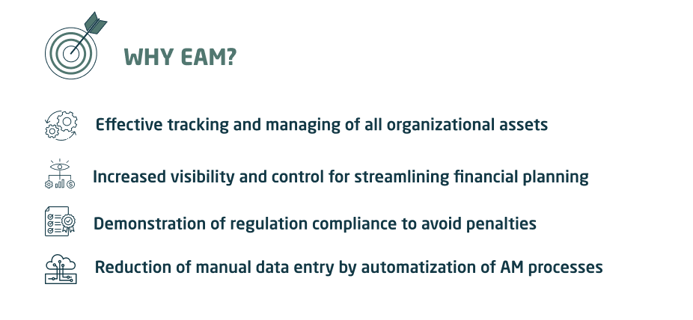

One of the key advantages of EAM software is that it enables the finance department to effectively track and manage all the organization's assets, including fixed assets, inventory, and equipment — all in one solution.

This integration allows for optimal asset utilization, reduced downtime, and avoidance of unnecessary maintenance or replacement costs. With the ability to store asset information in one centralized location, such as acquisition cost, depreciation, maintenance schedules, and disposal costs, you can make informed decisions about when to repair or replace assets, minimizing the risk of unexpected expenses.

But the benefits don't end there. Efficient asset management can also improve overall operational efficiency, as demonstrated by a study by ARC Advisory Group. According to the study, companies that use EAM software have seen an average increase of 24% in operational efficiency.

2. Increased Visibility and Control

EAM software provides greater visibility and control over the company's assets, which helps make data-driven decisions. By generating real-time reports and dashboards that show asset utilization rates, maintenance costs, and asset life cycles, you can identify areas where they can reduce costs, make accurate forecasts for future expenses, and plan for long-term capital expenditures.

By integrating EAM with an ERP system, organizations can streamline financial planning by identifying key areas of investment and cost-saving opportunities. According to research by Aberdeen Group, companies that use EAM software have seen an average increase of 32% in asset lifecycle management.

3. Improved Compliance

Another significant benefit of EAM software is its ability to ensure that the organization complies with regulations and standards related to asset management. By tracking maintenance schedules and repair history, the company can demonstrate compliance with safety and environmental regulations and avoid costly penalties. The software can also alert finance managers when assets are due for inspection or maintenance, ensuring that assets are safe, compliant, and not subject to penalties for non-compliance.

4. Better Financial Planning

Integrating EAM software with an ERP system can streamline processes by automating asset tracking, maintenance scheduling, and procurement processes, all while reducing manual data entry and potential errors. The added benefit is eliminating the need for multiple software systems, reducing IT maintenance costs. Furthermore, integrating EAM with an ERP system can improve data management, providing more accurate and up-to-date budgeting, forecasting, and financial reporting information.

Tracking asset depreciation, maintenance costs, and replacement needs more accurately can lead to better financial planning and forecasting, which is critical for organizations to make informed decisions about future investments. According to a report by TechValidate, 8.7 out of 10 companies that use EAM software have seen improvements in financial planning.

What about ROI?

As a financial advisor, you know that information is only valuable if you can translate it into a solid return on investment. So, let's cut through the chase and get to the heart of the matter by asking you three questions:

- How much do machine breakdowns cost your company, and what is the impact on production?

- Can you estimate the direct and indirect costs, including lost production time, increased maintenance expenses, and potential penalties for not meeting targets?

- How would such an event affect your relationships with customers or suppliers?

Please consider these costs carefully and compare them against the investment required to adopt an EAM system. According to a report by Nucleus Research, companies that invest in EAM software can expect an average ROI of 150%. But don’t get carried away with this data point because you can see real results in your own organization with a fully integrated system. The rewards are significant, potentially transforming the way you run operations for the better.

Investing in improving asset lifecycle management is a smart move for any asset-intensive company. Any percentage of ROI is a win because it means you're preventing breakdowns, meeting targets, and speeding up production—all of which translate to success for your company. We ask you to take a closer look at the potential ROI of an EAM system and consider the significant benefits it can bring to your bottom line.

Want to learn more? Download this eBook to learn the five advantages of having EAM directly built into Microsoft Dynamics 365 ERP and how to maximize financial performance with better asset management.

.png?width=388&height=200&name=Copy%20of%20Blog%20Featured%20Image%20(4).png)