What Is Preventive Maintenance?

Preventive maintenance is a systematic approach that facility managers proactively take to foresee and prevent equipment downtime before they take place. To do this, facilities management personnel undertake routine maintenance, equipment inspection, and asset repairs to make sure that everything runs as smoothly as the manufacturer intended.

Typical Preventive Maintenance programmes involve checklists for each piece of equipment which broadly include the following areas:

- A set schedule for routine inspections

- Regular cleaning

- Lubrication of moving parts

- Restoration of broken parts

Types of Preventive Maintenance

Preventive maintenance can either be time-based, usage-based, or a mixture of the two.

- Time-based Preventive Maintenance: This approach to preventive maintenance includes a set schedule where regular inspections will be conducted.

- Usage-based Preventive Maintenance: With a usage-based approach, facility managers conduct maintenance after a fixed amount of runtime. A good example is a vehicle, which one should send for servicing after it travels a certain mileage. Usage-based preventive maintenance is suitable for equipment with irregular usage and may reduce the number of times preventive maintenance needs to be performed.

Why using a CMMS System is Essential for Preventive Maintenance

The traditional method of performing preventive maintenance is with paper checklists. Clearly, using paper checklists is inefficient, difficult to monitor, prone to errors and environmentally unfriendly.

CMMS systems allow facility managers to digitize, automate assignment, track, store, and easily retrieve checklists. Specifically, the following are processes that can be performed with CMMS systems.

Easily Create Digital Checklists

Digital checklists can be created with an in-built form builder and schedules set as necessary. On the scheduled date, the checklist will appear in the “to-do” list and the appropriate technician will be alerted to complete the checklist.

Complete Checklists while on the Move

Mobile CMMS systems will allow technicians to use tablets or mobile phones to quickly complete the checklist on-site. This allows the technician to record progress while on the move. Photo and video evidence can also be attached to the checklist as proof of completion.

Sign off on Checklists Digitally

Say goodbye to the submission of paper checklists to be endorsed by supervisors. CMMS Systems typically have workflow features which can route completed checklists to the appropriate supervisors for sign-off. The amount of time saved when different parties can work digitally and asynchronously should not be underestimated. In this era of COVID-induced remote working, getting a physical checklist signed off in person is more difficult than ever.

Generate Maintenance Calendars

A calendar view is always useful for planning. Once checklists are scheduled, a calendar view can be automatically generated and sent to other affected parties to inform them of the maintenance calendar. As some maintenance activities may require temporary equipment downtime, affected parties need to be informed and make appropriate provisions to support the maintenance activity.

Ensuring Checks are Completed Satisfactorily

The discipline imposed by digital checklists which are scheduled by the system should not be overlooked. Once scheduled on the “to-do” list, the checklist needs to be completed or otherwise, an explanation needs to be recorded for skipping that check. The amount of time checklists spend in the “pending” or “processing” states can also easily be tracked and management reports automatically generated to measure aggregate checklist completion levels.

Easily Retrieve Checklists for Audits

With all checklists digitally stored, there is no need to maintain physical files. Clearly, this is an environmentally friendly practice. But more than that, searching for and retrieving digital checklists for audits takes seconds compared to what may be hours poring through physical files for the correct checklist. Note that there would most likely be no photo evidence available in the physical files also.

Data-Driven Decision Making

With CMMS systems, checklists can be digitally linked to assets. This allows the maintenance history of the asset to be easily retrieved and inspected. When was a particular asset last checked? Were there any issues found during the last inspection? Were these issues satisfactorily rectified? These questions can be easily answered in the CMMS system.

Asset replacement decisions can then be data-driven. If checks reveal consistent issues for a particular asset over several periods, then this may provide a reasonable basis to replace rather than repair the asset.

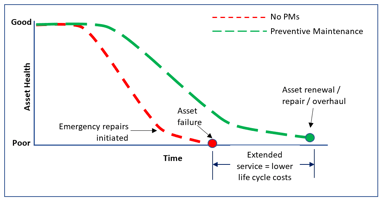

The Return on Investment

Preventive maintenance is a complex activity, particularly for large buildings with hundreds or thousands of assets. A well implemented digital preventive maintenance program can easily extract savings through lower equipment downtime, better asset replacement decisions and productivity savings.

With the availability of reasonably priced, cloud-based Software-as-a-Service Computerized Maintenance Management Systems, the Return on Investment for deploying CMMS systems to digital transform preventive maintenance is easily justified. One can even go so far as to say that there should be very little reason why a CMMS system should not be deployed to implement a preventive maintenance program, even for small or medium sized facilities.

.png?width=388&height=200&name=Copy%20of%20Blog%20Featured%20Image%20(4).png)

%20%5BConverted%5D-1.png?width=388&height=200&name=Illustration%20(45)%20%5BConverted%5D-1.png)