Strategic Guide to EAM built inside ERP

Improve reliability & reduce cost

A practical guide to optimizing enterprise asset management with unified ERP systems, strategies, key benefits, and real business outcomes.

Organizations use an average of 1,061 applications and yet only 29% are integrated.

Get strategic insights for your EAM & ERP strategy.

Disconnected asset data creates:

Direct costs from inaccurate information

Indirect costs from wrong decisions and lost reputation

Prevention, detection, and repair costs

The Hidden Financial Impact

When Asset Data Is Disconnected, ROI Suffers

When maintenance runs in one system and finance in another, data quality suffers and it becomes a financial problem

- 💸 The average cost of poor data quality is $12.9 million annually.

- 💸 29% of unplanned downtime is linked to disconnected systems.

- 💸 Up to 68% of incidents could be prevented with integrated monitoring.

- 💸 The world’s 500 largest companies lose nearly $1.4 trillion annually due to unplanned downtime.

Real Business Impact

Our customer highlighted in the guide

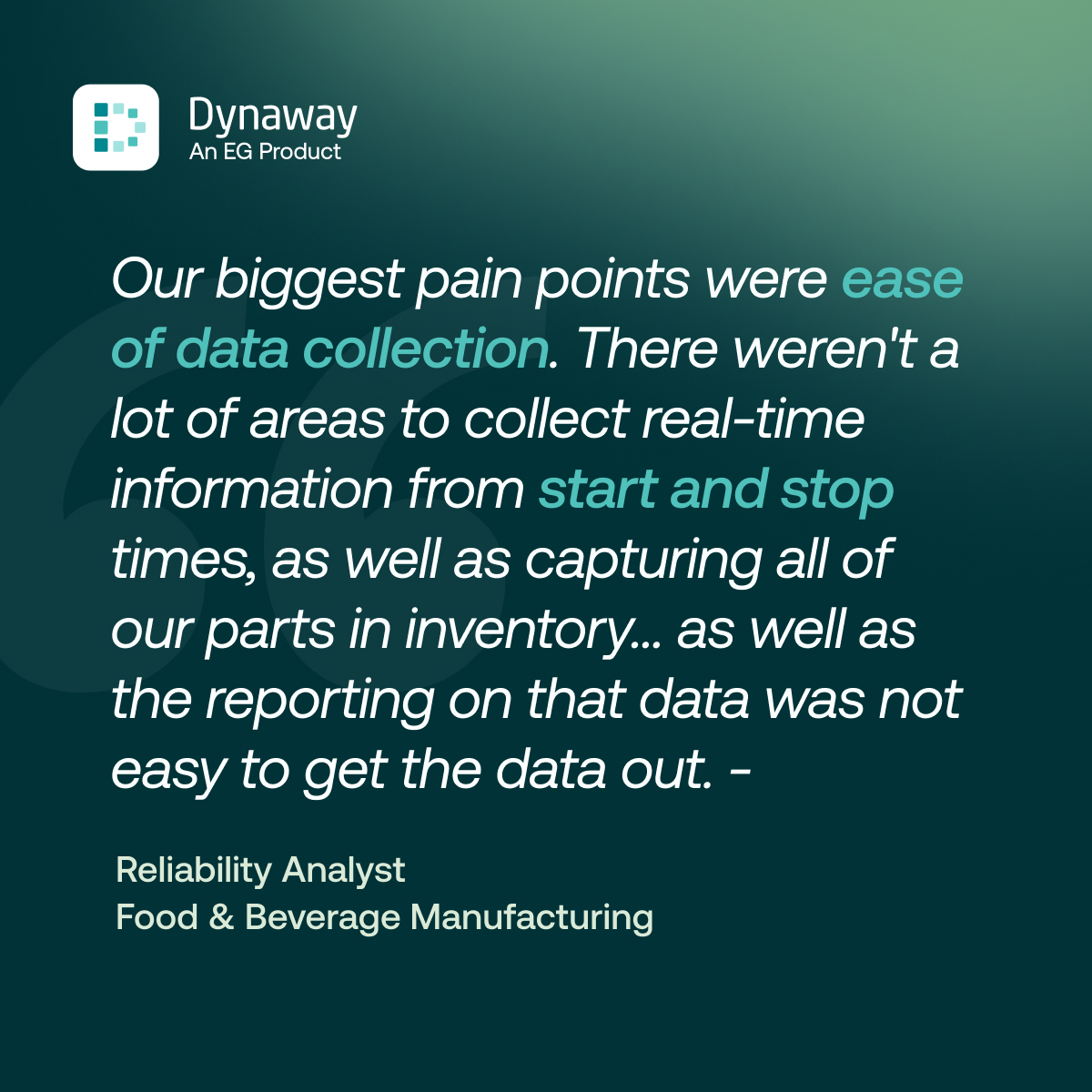

Disconnected systems are rarely intentional they evolve from departmental decisions, acquisitions, short-term budget choices, and lack of digital ownership.

As one customer noted:

“We needed a single source of truth.”

- 💰 Consolidated 25 disconnected systems into one ERP platform

- 💰 Migrated 35,000+ historical work orders into a unified system

- 💰 Achieved real-time cost and production visibility

- 💰 Eliminated manual reconciliation work

- 💰 Established a single source of truth across the organization

The Hidden Financial Impact

Scalability & Future Readiness

EAM inside ERP enables:

- 🔧 New facilities can adopt the same maintenance workflows without extra setup or customization.

- 🔧 Centralized data gives every site clear insight into performance, costs, and operational trends.

- 🔧 Built-in ERP capabilities support multi-site, multi-currency, and multi-language operations as you expand.

- 🔧 Emerging technologies plug into ERP easily, delivering value across maintenance, finance, and operations at the same time.

Scalability is only possible when data, devices, and operations are unified within one connected enterprise platform.

With EAM inside ERP, organizations gain

Repair vs. replace decisions grounded in lifecycle cost data

Budget optimization through real-time cost tracking

Production-linked procurement insights

Download the guide to understand how embedding EAM directly inside ERP improves uptime, cost control, efficiency, and long-term scalability.